Environmental pollution caused by plastic products has escalated and become a growing concern. A research team from Hong Kong Metropolitan University (HKMU) has studied the production of eco-bricks using plastic waste to promote the recycling and reuse of plastic. The new eco-bricks can reduce landfill waste by turning waste into treasure and provide the construction industry with another environmentally friendly building material. The eco-bricks outperform traditional bricks in terms of durability, waterproofing, and sound and thermal insulation and offer significant cost savings in construction projects. With a short-term patent granted by the Intellectual Property Department of Hong Kong, it is hoped that the eco-bricks will be widely used in the construction industry in the future to promote sustainable green building materials.

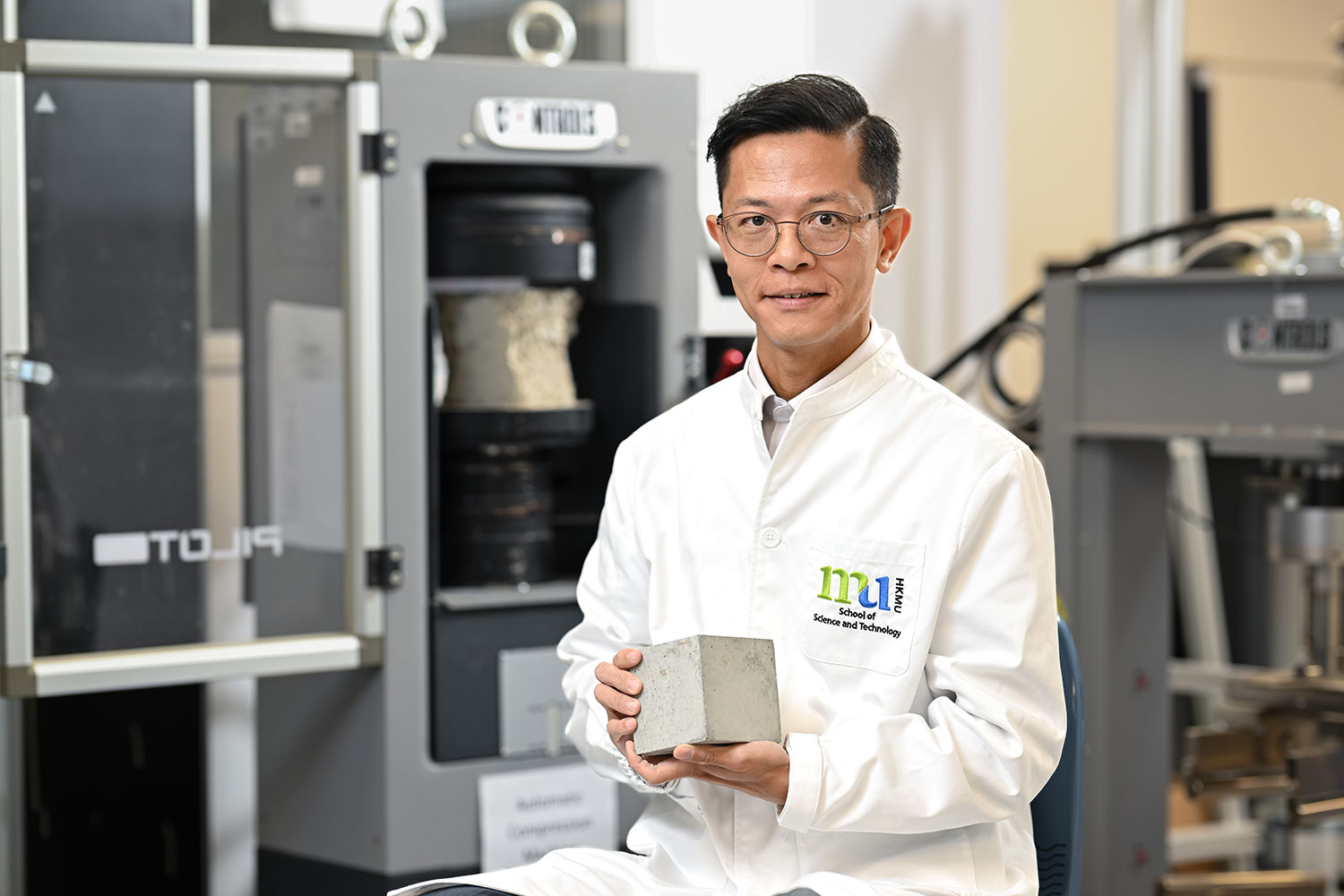

Dr Jimmy Li Chi-ho, Assistant Professor in the School of Science and Technology, and his team referenced previous research data to develop the eco-bricks by adding at least one type of thermoplastic crushed into small pieces, such as acrylonitrile butadiene styrene (ABS), nylon and polylactic acid (PLA), to common building materials, like gypsum, quick lime, sand and fly ash. Mixing all the materials into a composite and using compression moulding to shape the bricks provide a more durable building material at a lower cost than traditional sand bricks.

Data proves that eco-bricks are more pressure-resistant than traditional sand bricks

Eco-bricks with an appropriate amount of plastic added are significantly stronger than traditional sand bricks. Previous experimental data revealed that bricks with 5% waste plastic added to their composition achieved compressive strength of 4.5 N/mm², which is 8% higher than those without plastic, enabling them to withstand greater pressure without breaking. In addition, the unique structural design of eco-bricks significantly increases the water absorption rate from 7.8% to 9.2%, effectively preventing water seepage in buildings. The addition of plastic also improves the thermal insulation of the bricks, reducing the product's thermal conductivity by 10.2%, which helps reduce energy consumption and maintain a more comfortable indoor environment.

“According to a report by the United Nations Environment Programme, less than 10% of the seven billion tonnes of plastic waste generated globally has been recycled so far,” said Dr Li. “In view of this, the HKMU team studied the production of eco-blocks from plastic waste as an innovative, sustainable and environmentally friendly method to reduce plastic waste through recycling to diminish the reliance on incineration and landfills, thereby contributing to climate change mitigation.”

He added that the use of eco-bricks could reduce construction costs by about 5%, as plastic waste is typically cheaper than traditional sand. With mass production, the eco-bricks can provide significant economic benefits to the construction industry. Eco-bricks can also reduce the use of non-renewable resources such as sand and clay in production, thus reducing resource depletion.

Encouraging industrial applications to promote environmental protection

The research project received a grant of HK$875,000 from the University Grants Committee's Faculty Development Scheme and was granted a short-term patent by the Intellectual Property Department of Hong Kong in December 2023. Dr Li said the team would actively advocate research on eco-bricks and hoped that this brand-new material would be widely used in various construction projects in the future, contributing to the promotion of green buildings and sustainable development.